The process of greenteeth manufacturing is not as difficult as most people think. But there are a number of things that must be considered to ensure quality teeth. For the buyers that are going to the market, there are several things they need to know about the manufacturing. Otherwise, it is very easy to buy poor-quality green teeth for their stump grinders.

Here are key things that make ideal greenteeth manufacturing:

The Stump Grinder

The stump grinder is one of the first things that a manufacturer should be specific about. What type of stump grinder are you using, and does the manufacturer produce green teeth for it? This is an important question because there are so many types in the market, and each has specific needs. The horsepower, wheel size, and so on are just some of the factors to consider.

Types Stumps

The stump types also play a critical in green teeth manufacturing. There is a need to specify the kind of stumps that the machine can handle to produce the right teeth quality. The biggest mistake can be fitting the machine with a set of green teeth that do not match the kind of stumps being worked on.

The Soil Type

Most stump grinders users forget to factor in the issue of soil that they will be removed stamps from. The green teeth you have on the machine will also dig the soil when removing stumps. If the soil is rocky, you definitely need teeth that can withstand it. That’s why greenteeth manufacturing should factor soil type.

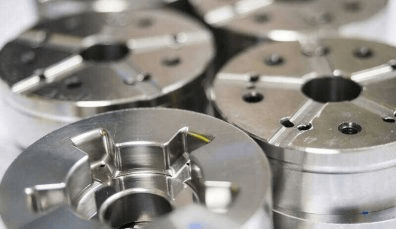

Raw Materials and Grades

The greenteeth manufacturing process usually uses steel for the body and carbide for the cutting head. These are the raw materials that are widely used in the construction of cutter tools. But there is the importance of putting more emphasis on the grade of these raw materials.

Manufacturing Technology

Many manufacturing technologies are used today, but forging is increasingly gaining traction. Cold forging is currently the most widely used, even for making the greenteeth. But hot forging is also being used as well, but cold and warm forging are increasingly growing popular.

Hardening Process

The best greenteeth manufacturing process must also take into consideration the hardening process. The stump removal process exposes cutter tools to a lot of wear and tear. That’s why the hardening process matters.

For all your green teeth needs, including the 700 series, click for info about a company that manufactures and supplies high-quality and affordable green teeth.